Room for ambition. No matter where and how far you fly, with the ION 6 nothing stands in the way of a personal best flight. But on this journey the fun does not fall by the wayside, because simple launch behaviour, pleasant handling and an effective speed system are included as standard. Or put differently, with the ION 6, both pilots new to the EN B class and (XC) professionals are well-equipped for every adventure - be it at the local site, when chasing kilometres or on paragliding trips.

Form follows function. The line length and thus the distance between the pilot and the canopy is significantly reduced on the ION 6. This results in more direct handling in the air as well as advantages during take off. For example, it requires less room to lay out the canopy and the wing inflates quickly and reliably. Additionally, the curvature of the wing has been reduced, meaning the canopy is “flatter”. This increases the roll damping and ensures stable flight. Due to the short lines, and despite the high roll damping, the ION 6 reacts precisely to brake inputs - and the pilot can feel what is happening above them without delay. Another consequence of the reduced curvature is the increased projected aspect ratio (3.84) compared to the ION 5 (3.52). However, the flat aspect ratio has increased by only 0.6%.

Relaxed from A to B. Successful cross-country flying requires complete concentration. The ION 6 makes this easy to do with its high level of passive safety, leaving you time to enjoy the view on the way. In flight, it quickly becomes clear that it can be turned particularly flat - i.e. you can’t “overcook it" when you want to fly a tight turn. This means you lose less height and can use even weak thermals effectively. But banking it higher, if you want a little more dynamics, is easily possible and this requires little brake travel and moderate brake pressure. In addition, the ION 6 has mini-ribs with internal seams, which increase the performance of the glider and ensure a smooth trailing edge. The other features built into the wing are a Mini-Rib Vector Tape and 3D Shaping at the leading edge.

Simply keep track of things. The ION 6 has specially designed adjustable risers. This system is also used, for example, on the MENTOR 6 (EN/LTF B) and the SECTOR (EN/LTF C). What does this mean? The A3 line is shortened less during acceleration than the A1 and A2 lines. This increased the stability of the wing during accelerated flight. Apart from that, the risers are standard and are very user-friendly on launch and during ground handling. The coloured markings for right and left, which also continue on the brake handles and the carabiners of our harnesses, make it easy to check whether you have hooked in correctly. By the way… line sorting is also easy, because the ION 6 has sheathed main, brake and stabilo lines and follows the colour scheme recommended by the PMA: A = red, B = yellow, C = blue, brake = orange, stabilo line = green.

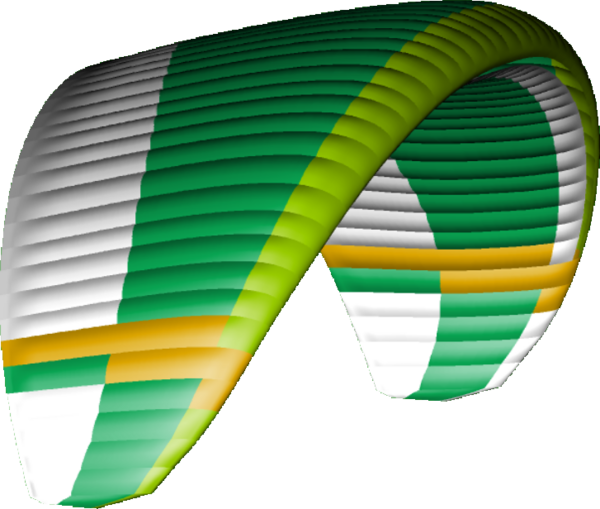

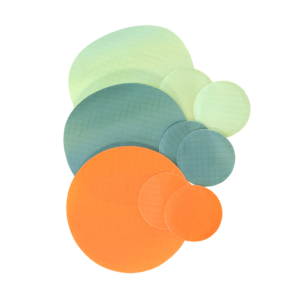

Green

Green

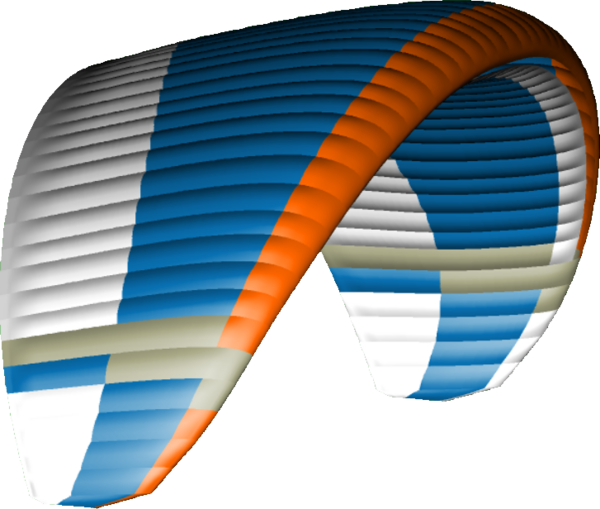

Blue

Blue

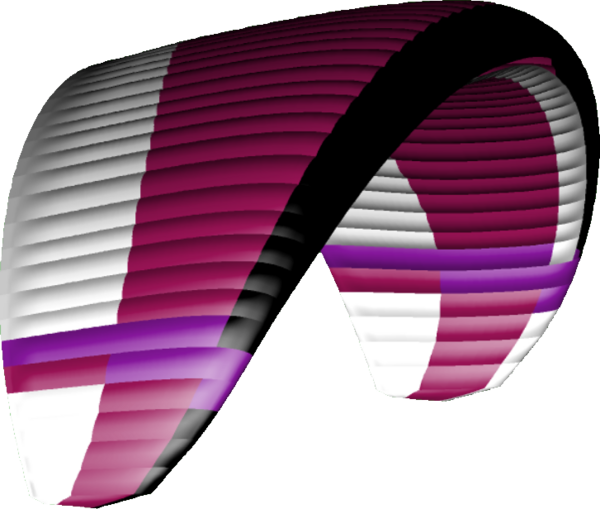

Sangria

Sangria

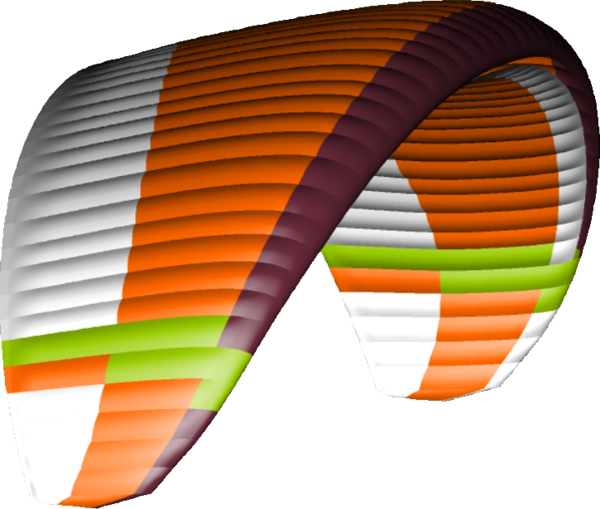

Orange

Orange

NOVA Stuff Sack.

NOVA Stuff Sack. NOVA Riser Bag.

NOVA Riser Bag. Manual.

Manual. Repair kit.

Repair kit. NOVA windsock.

NOVA windsock.