Adapted reefing system.

To dampen the opening force, the design of the PENTAGON Light has been adapted, inspired by the reefing system of round canopy parachutes. To ensure the opening force is applied more evenly to the canopy, the PENTAGON Light features spliced suspension lines. This design change results in a more damped opening of the rescue.

The ultimate in lightness.

Designed for hike & fly, climb & fly and vol biv, ultra-lightweight products are built to be as light and compact as possible. To achieve this, we use the lightest materials and technologies available - but never at the expense of safety! For the longest possible enjoyment of the product, we recommend particularly careful handling of the equipment.

Consistent at top speed.

Using thin webbing at the leading edge, the upper and lower surfaces are connected in the middle of each cell. This promotes leading edge solidity in flight, which is particularly beneficial to performance when flying at speed.

Think outside the box.

Instead of dividing the in-built rods and fixing both curved pieces with seams, the rods here simply form a loop. This saves on seams, supports the Air Scoop principle and has no disadvantages in terms of weight and packing volume.

Light, durable and suitable for everyday use.

Developed in line with the motto "as light as possible, and as solid as necessary", we rely on a smart design and choice of materials. Where possible, we use lightweight fabric, with sturdier cloth in the areas of heavier wear. This way we can guarantee long durability, high performance and easy handling with little weight. The paragliders are light, fully usable for everyday flying AND durable.

Two concepts combined.

A 2-liner at the wing tips, a 3-liner in the centre. This means this “2.5-liner” does not have a C3-line. Reduced line metres means less drag. Thanks to the two line areas at the wing tip, during acceleration an aerodynamically favourable wing twist is possible. This increases the performance in accelerated flight. The design also enables particularly efficient C-steering.

Self-towing.

The ELOWIN and ELOWIN SOLO can be operated with hand-held remote control in self-tow mode. We are currently working closely with the DHV to clarify the legal basis for self-towing. Once this is completed and permission is granted, we will start selling the necessary equipment for retrofitting.

Pay in & Pay out (payout & static operation).

Maximum flexibility. If there is traffic in the tow area (tractor, cyclist, etc.), it is easy to stop and continue the tow in a stationary position until the path is clear again. And all this with automatically controlled, constant towing power for the pilot.

Increased release altitude (maximum release height).

Simply go higher. All other things being equal (wind, thermals, topography, towing length), higher release altitudes are achieved compared to petrol engine winches. The reason for this is the constant and always maximum pulling force and correspondingly fewer pendulum movements of the glider.

Radio control system.

The best possible operation. The remote-controlled operation is carried out via control panel or hand-held remote control from the launch site. Radio contact is established several times a second. If there is no radio contact, the winch powers down and within a few seconds there is no longer pull on the cable.

Electrically actuated (efficient BLDC motor).

A tidy thing! Efficiency = 94%! Easy to operate and maintenance-free, because a brushless motor (Brushless DC) is used. By the way, the battery is recharged energy recirculation during payout operations - and neither the brake nor the torque converter gets hot.

Safe & steady traction (constant traction).

An algorithm makes it possible. The set maximum traction force is never exceeded and the traction force always remains constant. This ensures safe and smooth tows - regardless of the winch operator's dexterity.

Fewer lines, more performance.

One obvious advantage of two-liners is the reduction of drag caused by the lines. More important is the increased stability and the possibility of B-steering. The B-handles can be used to increase the angle of attack very directly and quickly without deforming the airfoil. Consequently, you can fly faster with the two-liner in lively air than with a three-liner.

Smooth profile nose.

Triple 3D-Shaping could be called an anti-wrinkle treatment for the nose of the wing: with three seams across the entire span of the top sail, we reduce the number of creases which are a consequence of the curvature over two axes. Two axes, because the sail cloth has to align to the profile form and the ballooning also determines a radius which the cloth also has to follow. It is as if trying to fold a piece of paper smoothly around a ball. It is impossible without creases. Triple 3D-Shaping divides the sections to be folded into smaller subsections. This allows us to get close to achieving the ideal crease-free form. The result: the creases on the profile nose are clearly reduced and this leads to better performance.

Zig-Zag 3D-Shaping.

In addition to the standard 3D Shaping there is a Zig-zag 3D Shaping seam on each cell. The advantage is that this seam doesn’t run in the direction of the spanwise force. This means the seam runs more cleanly and is more aerodynamically advantageous. This innovation reduces the creases in the leading edge.

Shaped in top form.

In 3D-shaping, a seam on the upper surface extends over the entire span and reduces the amount of folds caused by the curvature over two axes. Two axes, because the sail cloth has to align to the profile form and the ballooning also determines a radius which the cloth also has to follow.

Less knots, less wind resistance.

This wing has two line galleries: main lines and gallery lines, but there is no middle gallery. This means only very few line elements and as a result, they are very simple to sort.

Light as a feather and robust.

Very light but still durable: Light weight NOVA wings weigh little but are still robust enough to withstand the hard conditions of the mountains. The profiles are made out of durable cloth, so that this highly-stressed component does not deform - like it can with ultra-light material. This means we are able to guarantee consistent flying characteristics.

Clever connections.

Needle-eye Ribs are innovative ribs which traverse the profile through slots. This results in a more precise shape than is achieved in a conventional four or five piece rib, which is implemented using multiple-piece diagonal ribs, each sewn onto the cell walls. The consequence is a more rigid aerofoil and higher performance.

Flat profile nose.

Anyone who tries to fold a piece of paper around a ball will notice that there are always creases. The nose profile of a paraglider is the same - the sail cloth has to adjust to both the profile and ballooning effect (cells are round, not straight). Double 3D Shaping uses additional seams to reduce creasing and therefore increases the performance of the wing.

Under pressure.

NOVA Air Scoop is an optimised air intake, which increases the internal wing pressure. NOVA's Air Scoop principle is similar to the ram-air inlet duct on a sports car: increased airflow produces higher pressure. Higher internal pressure in a paraglider means improved performance through increased structural stability and collapse resistance.

Less is more.

Our idea of a three-liner with a reduced amount of line length allows us to construct wings with very good performance and a high degree of passive safety. The way we have conceptualised the lines has made it possible to manufacture wings which are collapse resistant; but when they do collapse, the collapsed area is generally less extensive. This significantly improves the wing's extreme flight behaviour.

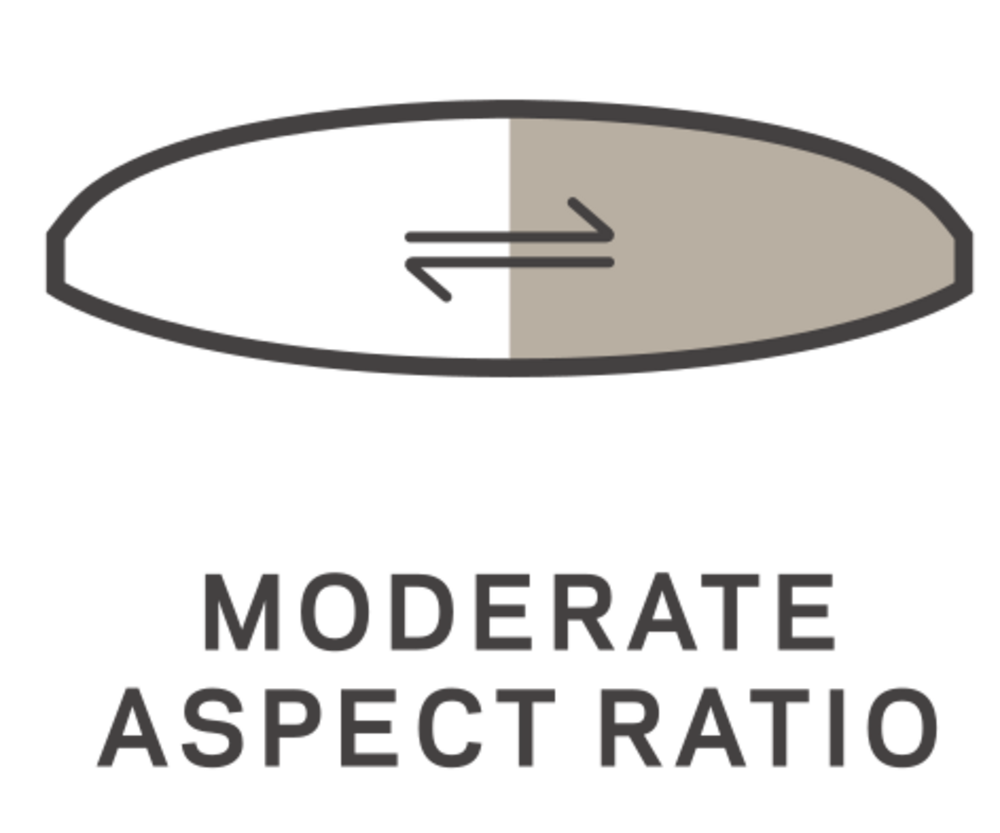

More compact.

The aspect ratio of a glider is not the only factor in passive safety, but still a very important one. A high aspect ratio favours cravats after asymmetric collapses, generally shortens brake travel and normally makes wings more difficult to fly. Nova's analytical tools permit us to build performance wings even with a low or moderate aspect ratio.

Comfort on the ground.

All NOVA paragliders are made to be easy to use. For packing you can use a concertina bag, but it is not essential. Our extensive experience with rods has taught us that the packing method has little influence on the durability of the wing. Bent rods quickly spring back into their original shape.

Easy Repacking.

All base lines of the PENTAGON and PENTAGON Light are all the same length and colour-coded. Also all lines are equal distance from each other. Using the packing loops, the PENTAGON and PENTAGON Light are very easy to pack and the risk of mistakes is minimal.